POWDER COATING

>> For durable and wear-resistant surfaces .

-

ADVANTAGES

Powder coating offers an eco-friendly, durable, and corrosion-resistant surface treatment that resists scratches, fading, and rust, extending the lifespan of your products.

-

MAX STORLEK

Om vi kan skära det, kan vi pulverlackera det.

Vår beläggningskapacitet matchar våra skärdimensioner! -

9 FÄRGER, BLANK ELLER MATT FINISH

Välj mellan blank eller matt yta i svart, vitt, gult, ljusgrått, mörkgrått, rött, blått, grönt och orange.

Professional

surface treatment.

>> High durability

>> Corrosion-resistant

>> Eco-friendly process

>> Extends lifespan

>> Premium finish

Powder coating is a surface treatment method that creates a durable and weather-resistant finish by applying a dry powder to metal surfaces. The powder is then cured in an oven at high temperature to create a smooth and durable surface.

This process provides a long-lasting finish that not only looks great but also protects your products from scratches, rust, and UV radiation. With our expertise and advanced technology, we offer powder coating as an addition for various types of projects, from small details to larger quantities.

At Scandcut.se, you get the price directly with no waiting time! *

* When you choose powder coating for your order, it will add 5 - 10 extra days to the total production time.

Surface treatment

that delivers protection.

>> Durability: Powder coating provides long-lasting protection against weathering, scratches, and wear.

>> Eco-friendly: No solvents are used – better for both you and the environment.

>> Aesthetics: A smooth, high-quality finish that stays looking great over time.

>> Flexibility: Perfect for both small and large orders, get your price instantly through our online software – no waiting for the price! *

* When you add powder coating to your order, it will add 5 - 10 extra days to the total production time.

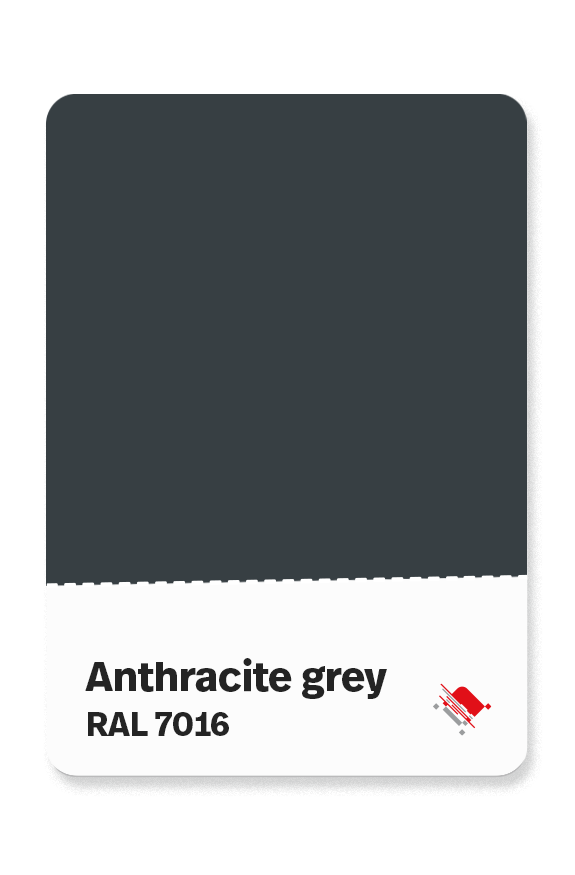

Scandcut & RAL® CLASSIC colour system

At Scandcut, we use RAL® to guarantee color consistency and stability. Of the 215 shades available in the RAL® CLASSIC scale, we have selected 9 standard colors to ensure that the quality and color match industry standards.

These colors are available in two finishes: gloss 80 and matte gloss 30

* Please note that these colors are the only options we offer for powder coating.

Easily order your powder-coated parts online.

“Powder coating is a durable and aesthetic surface treatment that protects and enhances the quality of your orders. Through Scandcut.com, we’ve made it possible with just one click – no more waiting for quotes!”

Our process

for powder coating

We use a carefully controlled process to ensure that each product receives the highest quality powder coating. Here are the steps in the process:

>> Preparation: To achieve the best possible result, the product is thoroughly cleaned and degreased.

>> Primer application: A layer of primer is applied to the product to ensure the best possible adhesion and durability for the powder coating.

>> Powder application: Powder is evenly applied to the surface of the product. Powder coating adds a layer between 80–120 µm (including primer and topcoat).

>> Curing: The product is heated in an oven to cure the powder and create a durable surface.

>> Quality control: After the powder coating has cured, the product is carefully inspected to ensure the result meets our high standards.

Frequenctly asked questions about powder coating:

-

Absolutely, you can easily combine powder coating with laser cutting and bending – all online with instant pricing!

-

When you add powder coating to your order, the production time is extended by 5 - 10 days, regardless of the quantity.

-

Unfortunately, no – these colors are the only options we offer for powder coating.

For larger orders, business agreements, or productions, we can discuss the possibility of offering colors other than the 9 RAL® standard colors listed. Please contact us at support@scandcut.com to discuss your specific needs.

-

We always strive to deliver products of the highest quality. If for any reason you are not satisfied with the result, please contact us as soon as possible at support@scandcut.com.

-

Powder coating adds a layer between 80–120 µm (including primer and topcoat). It is important to note that we do not cover or plug holes before coating. Ensure that your CAD file accounts for this dimensional change if it is relevant to fit or function.

Upload your file – get instant pricing!

With our advanced online service, you can seamlessly combine laser cutting, bending, and powder coating for a complete product, quickly and easily.